Product Center

Product Center

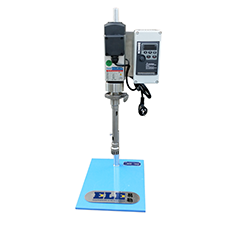

ELR /3 In-line High Shear Mixer

category:

Continuous Emulsifier

Home Products

- 产品描述

- parameter

-

- Commodity name: ELR /3 In-line High Shear Mixer

- Commodity ID: 1019654965741576192

Product summary: Special desinged rotor-stator work head which is precision finishing. Widely used in chemical production, liquid liquid with liquid, liquid with powder, high efficiency, processing time get quite shorter.

Introduction

Special desinged rotor-stator work head which is precision finishing. Widely used in chemical production, liquid liquid with liquid, liquid with powder, high efficiency, processing time get quite shorter.

Features

- there are three stage in the working chamber, they are 2-layers, 4-layers and 6-layers stator and rotors, it can get micronemulsion result.

- suitable for large quantity conituous production.

- applicable for liquid product with various viscosity

- according to PH, the material can be sus304 or sus316L stainless steel

- precision finishing rotor-stator which is linear cutting

- ideal gap between rotor-stator, advanced processing result and short working time.

- elastic connection, low noise

- doulble-end mechanical seal, also can design water level switch according to process need

Specifications

Model Power/kw Rotation/rpm Flow/m3/h Entrance Exit Material ELR401/3 1.1/1.5 3000 0.5 DN40 DN32 SUS304/316L ELR405/3 4 3000 2 DN40 DN32 SUS304/316L ELR410/3 7.5 3000 4 DN50 DN40 SUS304/316L ELR415/3 11 3000 6 DN60 DN50 SUS304/316L ELR420/3 15 3000 12 DN60 DN50 SUS304/316L ELR425/3 18.5 1500/3000 16 DN60 DN50 SUS304/316L ELR430/3 22 1500/3000 18 DN60 DN50 SUS304/316L ELR450/3 37 1500 26 DN100 DN80 SUS304/316L ELR460/3 45 1500 30 DN125 DN100 SUS304/316L ELR475/3 55 1500 32 DN125 DN100 SUS304/316L ELR490/3 75 1500 45 DN125 DN100 SUS304/316L ELR510/3 90 1500 55 DN125 DN100 SUS304/316L ELR530/3 110 1500 70 DN150 DN125 SUS304/316L Options

- motor power according to processing quantity of the reactor.

- complete ex-proof motor according to process

- with jacket to cool during processing.

-

-

parameter

- 1

- 2

- 3

- 4

-

Product Description

Introduction

Special desinged rotor-stator work head which is precision finishing. Widely used in chemical production, liquid liquid with liquid, liquid with powder, high efficiency, processing time get quite shorter.

Features

- there are three stage in the working chamber, they are 2-layers, 4-layers and 6-layers stator and rotors, it can get micronemulsion result.

- suitable for large quantity conituous production.

- applicable for liquid product with various viscosity

- according to PH, the material can be sus304 or sus316L stainless steel

- precision finishing rotor-stator which is linear cutting

- ideal gap between rotor-stator, advanced processing result and short working time.

- elastic connection, low noise

- doulble-end mechanical seal, also can design water level switch according to process need

Specifications

| Model | Power/kw | Rotation/rpm | Flow/m3/h | Entrance | Exit | Material |

| ELR401/3 | 1.1/1.5 | 3000 | 0.5 | DN40 | DN32 | SUS304/316L |

| ELR405/3 | 4 | 3000 | 2 | DN40 | DN32 | SUS304/316L |

| ELR410/3 | 7.5 | 3000 | 4 | DN50 | DN40 | SUS304/316L |

| ELR415/3 | 11 | 3000 | 6 | DN60 | DN50 | SUS304/316L |

| ELR420/3 | 15 | 3000 | 12 | DN60 | DN50 | SUS304/316L |

| ELR425/3 | 18.5 | 1500/3000 | 16 | DN60 | DN50 | SUS304/316L |

| ELR430/3 | 22 | 1500/3000 | 18 | DN60 | DN50 | SUS304/316L |

| ELR450/3 | 37 | 1500 | 26 | DN100 | DN80 | SUS304/316L |

| ELR460/3 | 45 | 1500 | 30 | DN125 | DN100 | SUS304/316L |

| ELR475/3 | 55 | 1500 | 32 | DN125 | DN100 | SUS304/316L |

| ELR490/3 | 75 | 1500 | 45 | DN125 | DN100 | SUS304/316L |

| ELR510/3 | 90 | 1500 | 55 | DN125 | DN100 | SUS304/316L |

| ELR530/3 | 110 | 1500 | 70 | DN150 | DN125 | SUS304/316L |

Options

- motor power according to processing quantity of the reactor.

- complete ex-proof motor according to process

- with jacket to cool during processing.

Key words:

ONLINE MESSAGE

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Related Products