Product Center

Product Center

Pneumatic Lift Highs Shear Mixer

category:

Batch Emulsifier

Home Products

- 产品描述

- parameter

-

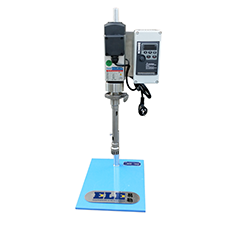

- Commodity name: Pneumatic Lift Highs Shear Mixer

- Commodity ID: 1019650450065809408

Product summary: High Shear Mixer with precision rotor and stator. It is suitable for all kind of liquid chemical production.

Introduction

Special desinged rotor-stator work head which is precision finishing. Widely used in chemical production, liquid liquid with liquid, liquid with powder, high efficiency, processing time get quite shorter.

Features

- precision finishing rotor-stator which is linear cutting

- ideal gap between rotor-stator, advanced processing result and short working time.

- claw-structure, drawing material from the bottom of tank into the centre of work head, because of the centrifugal force speed up the toward the side of work head.

- pneumatic lift frame with wheels at the bottom, make the machine flexible and save space.

- it is more suitable for small amount of batch production.

Specifications

Model Main Power/kw Rotation/rpm Capacity/L Stroke/mm Material EBR-1.1 1.1 3000 <100 600 SUS304/316L EBR-4 4 3000 <200 800 SUS304/316L EBR-7.5 7.5 3000 <500 900 SUS304/316L EBR-11 11 3000 <800 900 SUS304/316L EBR-15 15 1500/3000 <1200 900 SUS304/316L EBR-18.5 18.5 1500/3000 <1800 1100 SUS304/316L EBR-22 22 1500/3000 <2000 1100 SUS304/316L EBR-30 30 1500 <2500 1100 SUS304/316L EBR-37 37 1500 <3000 1600 SUS304/316L EBR-45 45 1500 <4000 1600 SUS304/316L EBR-55 55 1500 <5000 1600 SUS304/316L Options

- complete ex-proof motor according to process

- vessel according to need

- motor power according to product to be processed and quantity.

-

-

parameter

- 1

- 2

- 3

- 4

-

Product Description

Introduction

Special desinged rotor-stator work head which is precision finishing. Widely used in chemical production, liquid liquid with liquid, liquid with powder, high efficiency, processing time get quite shorter.

Features

- precision finishing rotor-stator which is linear cutting

- ideal gap between rotor-stator, advanced processing result and short working time.

- claw-structure, drawing material from the bottom of tank into the centre of work head, because of the centrifugal force speed up the toward the side of work head.

- pneumatic lift frame with wheels at the bottom, make the machine flexible and save space.

- it is more suitable for small amount of batch production.

Specifications

| Model | Main Power/kw | Rotation/rpm | Capacity/L | Stroke/mm | Material |

| EBR-1.1 | 1.1 | 3000 | <100 | 600 | SUS304/316L |

| EBR-4 | 4 | 3000 | <200 | 800 | SUS304/316L |

| EBR-7.5 | 7.5 | 3000 | <500 | 900 | SUS304/316L |

| EBR-11 | 11 | 3000 | <800 | 900 | SUS304/316L |

| EBR-15 | 15 | 1500/3000 | <1200 | 900 | SUS304/316L |

| EBR-18.5 | 18.5 | 1500/3000 | <1800 | 1100 | SUS304/316L |

| EBR-22 | 22 | 1500/3000 | <2000 | 1100 | SUS304/316L |

| EBR-30 | 30 | 1500 | <2500 | 1100 | SUS304/316L |

| EBR-37 | 37 | 1500 | <3000 | 1600 | SUS304/316L |

| EBR-45 | 45 | 1500 | <4000 | 1600 | SUS304/316L |

| EBR-55 | 55 | 1500 | <5000 | 1600 | SUS304/316L |

Options

- complete ex-proof motor according to process

- vessel according to need

- motor power according to product to be processed and quantity.

Key words:

previous

previous

ONLINE MESSAGE

*Note: Please be sure to fill in the information accurately and keep the communication open, we will get in touch with you as soon as possible

Related Products